Revolutionizing Liquid Nitrogen Injection Systems: The Innovation of Linear Push-Pull Automatic Valves with GEKO

Jan 30, 2026

Introduction

In the world of cryogenics, particularly in liquid nitrogen injection systems, traditional valves, such as angle valves, have long relied on manual operation with a rotational structure and threaded components. This setup requires operators to wear heavy protective gear in extremely cold environments, reducing efficiency and introducing significant safety risks. This article explores a groundbreaking solution that replaces manual valves with automated ones driven by pneumatic or electric actuators. By incorporating a linear push-pull mechanism instead of the traditional rotational structure, this innovative design offers improved performance, speed, and safety, making it an ideal solution for low-temperature fluid control. GEKO, a trusted name in valve technology, has embraced this innovation to deliver high-performance solutions for critical cryogenic applications.

Limitations of Traditional Manual Valves

Traditional angle valves in liquid nitrogen systems face numerous challenges:

1) Low Operational Efficiency: The time-consuming manual rotation of the valve stem delays response time, especially in emergencies.

2) Poor Low-Temperature Adaptability: Threaded structures are vulnerable to cold contraction, leading to seal failure or component wear, which increases the risk of leaks.

3) Safety Hazards: Operators are exposed to extreme cold, and the cumbersome manual operation, often hindered by thick gloves, can lead to errors that jeopardize both personnel and equipment safety.

4) High Maintenance Costs: Frequent seal inspections and component replacements drive up long-term operational expenses.

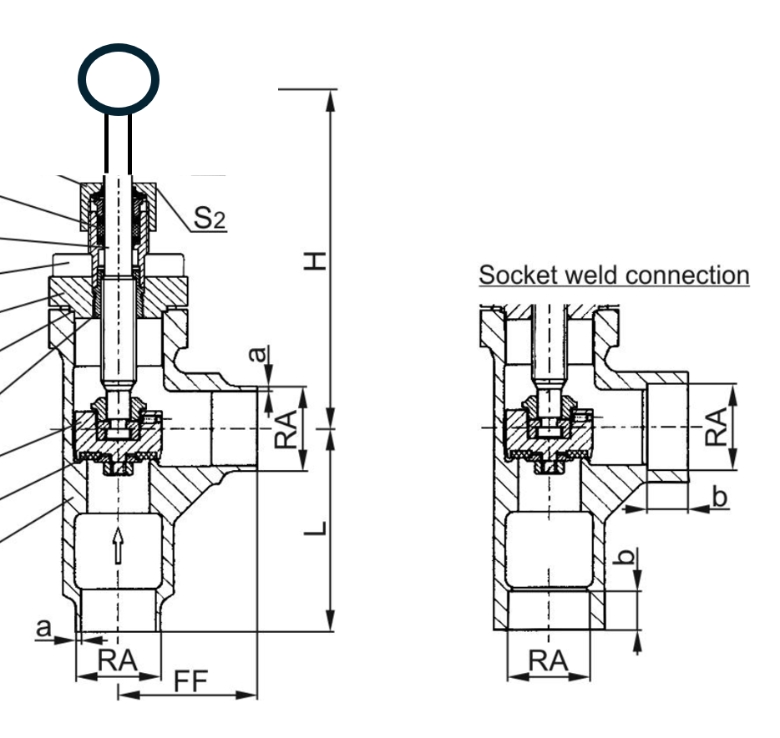

The Solution: Linear Push-Pull Automatic Valves

The core innovation involves replacing manual valves with automatic valves powered by pneumatic or electric actuators, offering a linear push-pull motion instead of the traditional rotational movement:

1) Pneumatic Actuators: These utilize compressed air to drive a piston, allowing for rapid valve opening and closing, ideal for high-frequency operations.

2) Electric Actuators: Electric motors power gears or screw mechanisms to achieve precise linear movement, making it easier to integrate with automated control systems.

3) Linear Push-Pull Mechanism: Eliminating the need for rotational movement simplifies the operational process, reduces component wear, and extends the lifespan of the valve.

Optimized for Low-Temperature Environments

To address the extreme cold of liquid nitrogen (-196°C), the upgraded design includes the following features:

1) Material Selection: Stainless steel or special alloys are used to ensure structural stability and leak-proof performance even in low temperatures.

2) Self-Sealing Mechanism: The valve automatically forms a seal when closed, preventing leakage due to cold contraction and ensuring reliable operation.

3) Freeze Protection: Actuators are equipped with heating elements or insulation layers to prevent freezing of the moving components, ensuring continuous operation.

Enhancing Safety and Efficiency

- Improved Operator Convenience: The linear push-pull movement simplifies valve operation, eliminating the need for complex training. Operators can control the valve remotely via a control panel, further reducing the exposure to hazardous environments.

- Faster Response Time: Linear motion is quicker than rotational movements, reducing the time taken to open and close the valve, thus increasing system throughput.

- Enhanced Safety: The reduction of manual intervention decreases the likelihood of operator errors, reducing the risk of leaks and equipment damage. The design adheres to the strictest safety regulations.

- Reduced Maintenance: The self-sealing design and the simplified linear structure minimize component wear, lowering maintenance frequency and extending the valve's service life.

Applications and Benefits

Liquid Nitrogen Injection Systems

In liquid nitrogen injection applications, the modified automatic valve system delivers exceptional results:

- Rapid Injection: The linear push-pull drive quickly opens the valve, significantly improving the speed of nitrogen injection and reducing waiting times.

- Reliable Sealing: The optimized sealing mechanism ensures stability even in low temperatures, preventing leaks and guaranteeing safe operations.

- Simplified Operation: The pneumatic or electric control options support remote operation, minimizing the risk of personnel exposure to low-temperature environments, thus enhancing safety.

Other Cryogenic Fluid Systems

This innovation can be extended to other cryogenic fluids such as liquid oxygen or carbon dioxide, providing similar improvements in operational convenience and safety. The solution is ideal for laboratories, medical facilities, and industrial applications where low-temperature fluids are critical.

Conclusion

The conversion of traditional manual angle valves to automatic valves driven by pneumatic or electric actuators with a linear push-pull mechanism represents a revolutionary shift in cryogenic fluid control. This innovation significantly improves operational convenience, system efficiency, and safety while reducing maintenance requirements. GEKO, with its cutting-edge technology, offers this solution not only for liquid nitrogen injection systems but also for a wide range of cryogenic applications, ensuring a more reliable and efficient way to manage low-temperature fluids. This advancement marks a significant step forward in the industry, offering enhanced performance and reliability for the most demanding environments.

LEIA MAIS